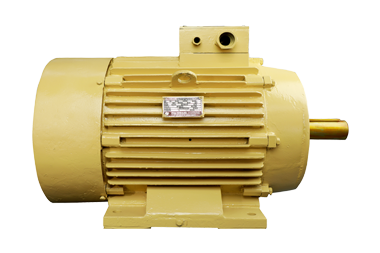

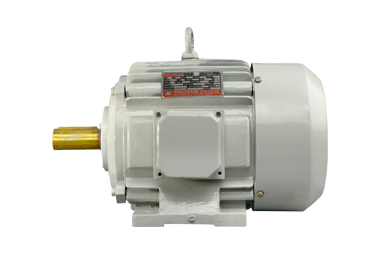

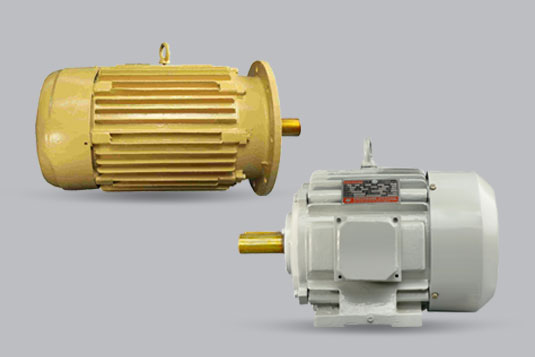

IE3 Efficiency Induction Motors

Premium Efficiency Induction motor with low maintenance costs

An induction motor (also known as an asynchronous motor) is a commonly used AC electric motor. Induction motor are the most frequently-used type of motor used in residential, commercial, and industrial settings so far. In an induction motor, the electric current in the rotor needed to produce torque is obtained via electromagnetic induction from the rotating magnetic field of the stator winding.

Defence

Material Handling

Machine Tool

Textile

In an AC motor, there's a ring of electromagnets arranged around the outside (making up the stator), which are designed to produce a rotating magnetic field. Inside the stator, there's a solid metal axle, a loop of wire, a coil, a squirrel cage made of metal bars and interconnections

These energy efficient motors are designed to minimize losses both in the core and in the windings It will give better efficiencies at partial loads (50 %, 75 %). Thus, there will be lesser generation of heat while ensuring superior performance.

Induction Motors brochure Download

Product Details

| Electrical Specifications | 065-OD | 100-OD | 150-OD | 230-OD | 410-OD | ||||

|---|---|---|---|---|---|---|---|---|---|

| Specification | Unit | T-I-065-18-07-N-AB | T-I-065-54-35-N-AB | T-I-100-60-40-N-AA | T-I-150-38-91-N-AA | T-I-230-35-130-N-AB | T-I-410-45-235-N-AA | ||

| Continuous Torque | Nm | 0.25 | 1 | 4 | 8 | 16 | 70 | ||

| Continuous Current | A | 2.9 | 2.2 | 9.5 | 5.5 | 11.5 | 28 | ||

| Phases | 3 | 3 | 3 | 3 | 3 | 3 | |||

| Kt (Torque Constant) | Nm /Amp | 0.086 | 0.454 | 0.421 | 1.454 | 1.390 | 2.5 | ||

| Ke (Voltage Constant) | V/Krpm | 7 | 35 | 40 | 91 | 130 | 235 | ||

| Km (Motor Constant) | Nm/√𝑊 | 0.075 | 0.242 | 0.538 | 1.156 | 1.880 | 7.21 | ||

| Resistance | Ohm | 1.322 | 3.52 | 0.612 | 1.33 | 0.548 | 0.12 | ||

| Poles | 8 | 8 | 12 | 24 | 48 | 64 | |||

| Mechanical Specifications | |||||||||

| Stator OD | mm | 65 | 65 | 100 | 152 | 230 | 410 | ||

| Stator ID | mm | 35 | 35 | 65 | 108 | 184 | 332 | ||

| Rotor OD | mm | 33.3 | 33.3 | 63 | 106.5 | 183 | 330 | ||

| Rotor ID | mm | 17 | 17 | 43 | 89 | 160 | 290 | ||

| Air Gap | mm | 0.85 | 0.85 | 1 | 0.75 | 0.75 | 1 | ||

| Stator Length | mm | 18 | 54 | 60 | 38 | 35 | 45 | ||

| Stator Height | mm | 10 | 44 | 40 | 26 | 20 | 25 | ||