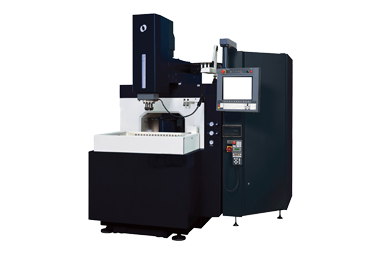

Electric Discharge Machine (EDM)

Electric discharge machining (EDM) cuts or shapes the workpiece using a metallic wire.

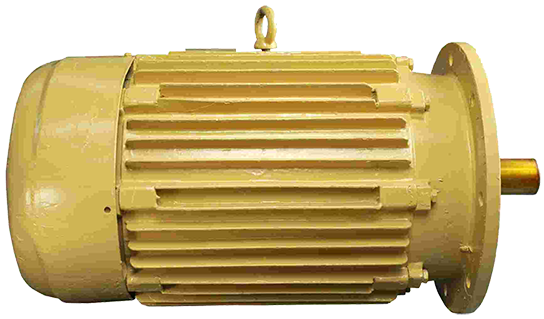

This wire is often a conductive material, with a thin electrode wire that follows a precisely programmed path. A motor that can deliver the desired speed and tight control is an essential part of the EDM machining process. The motor is directly responsible for the movement of the axis of the EDM machine.

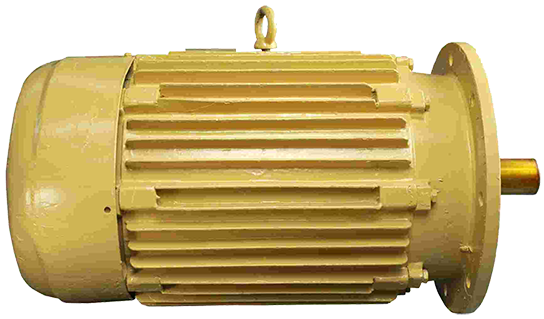

Pranshu Electricals has over a decade of experience and expertise in manufacturing motors that are best suited for EDM machines.

Motors used in this application:

- EBT4830 - 48 V, 3000 rpm, 5.3 amps, 0.6Nm

- DA2430 - 24 V, 3000 rpm, 3 amps, 0.2Nm

- EB7530 - 75 V, 3000 rpm, 3 amps, 0.6Nm