Electric motors basically produce motion from electric power. Motors are critical to a host of activities ranging from manufacturing to transportation and even toys. Permanent magnet DC motor is an advanced type of motor similar to induction motors. It utilizes the power of electromagnetic principles to generate torque. As the name indicates, this motor uses a permanent magnet to create the magnetic field for operating the DC motor.

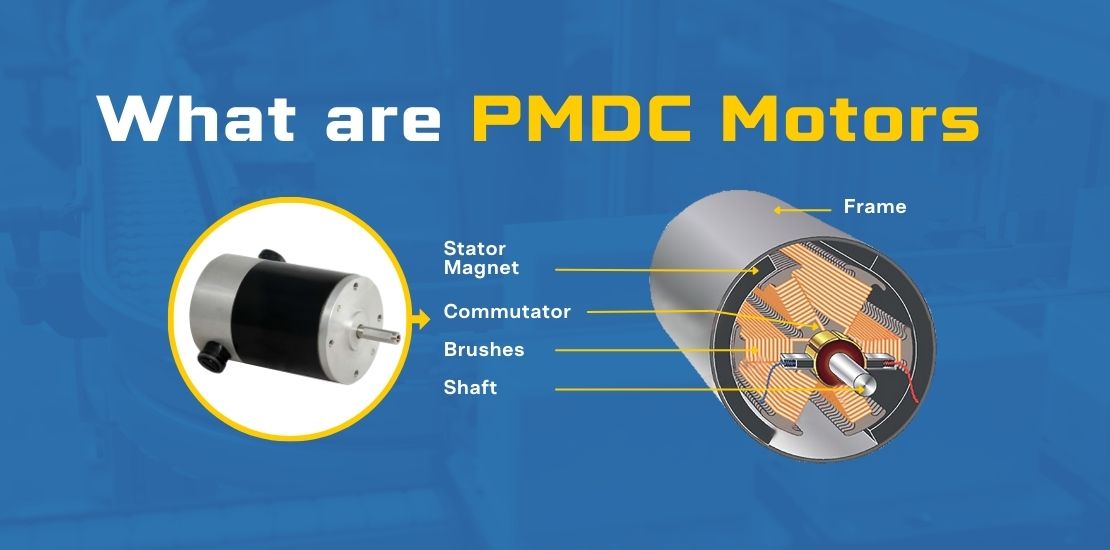

Components of a PMDC motor

A PMDC motor has two major components

Stator

The stator is the outer part of the PMDC motor which makes up its housing. Magnets are mounted on the inner side of the stator in such a way that the North and South pole of the magnets alternatively face the armature. Apart from housing the magnets, the stator also serves as a low reluctance return path for the magnetic flux. In case the magnets somehow lose their power, an additional field coil is provided to compensate for the same.

Armature

The armature is the moving part of the PMDC motor which consists of winding, core, and commuter, and connects to the output shaft of the motor. In other motors, the rotor generates its own magnetic field by using a DC power source or induction. In other cases, it is simply made up of a ferromagnetic metal. PMDC motors however feature a different mechanism.

The core of the armature consists of laminations of steel sheets that are slotted circular and varnish insulated. The seel sheets work to reduce eddy current loss in the rotor.

The armature comprises slots containing armature winding. The commuter of the armature will be supplied with current by the brushes. It will then convert electrical power into motion. The armature is powered by connecting the brushes terminals to the DC supply.

The PMDC motor is considered to be a synchronous motor because the magnets within the motor are capable of achieving speeds equal to the excitation current.

Magnets used in PMDC motors

Magnets used in PMDC motors come from three types of materials

Alnicos magnets

Alnicos feature a high residual flux density and low coercive magnetizing intensity. Hence, they are mostly used in applications where a low current is required at high voltage.

Ferrite magnets

Ferrite magnets tend to be lower in costs are are used in PMDC motors for cost-sensitive applications such as refrigerators, AC units or compressors.

Rear earth magnets

Rear earth magnets are composed of neodymium-iron-boron or of samarium cobalt. They feature a high coercive magnetizing intensity and high residual flux. These magnets do not suffer demagnetizing issues due to armature reactions.

Rear earth magnet materials tend to be quite expensive. Within these, Neodymium iron boron costs lower than samarium cobalt, and can also withstand high temperatures. Rear earth magnets are used in PMDC motors for size-sensitive applications including automobiles, servo industrial drives and in large industrial motors.

Working principle of permanent magnet DC motor

There is not much difference between the basic operating principle of the PMDC motor. When an electrical conductor is introduced within the magnetic field, the conductor experiences a mechanical force. The direction of this force is governed by Fleming’s left-hand rule.

In the case of the PMDC motor, the armature is placed within the magnetic field created by the permanent magnets placed inside the stator. The armature will then rotate according to the force generated. The armature has a number of conductors, each of which experiences the force which is then converted into torque, leading the armature to rotate.

Typically, the PMDC motor operates on 6 V, 12 V or 24 Volts DC power which can be provided by rectifiers or batteries. The torque is generated by the interaction between the axial current-carrying rotor conductors and the magnetic flux produced by the permanent magnet.

The position among the stators and the armature can be reduced as the armature rotates due to the torque created by a magnetic field. Te shift in position can reverse the torque in a 90-degree rotation. The commutator set to the rotor shaft of the PMDC motor maintains the torque performing on the rotor.

The current supply towards the stator is activated by the commuter. This helps maintain a steady 90-degree angle among two fields. As the flow of current is frequently activated among windings like the rotor twists, then the current within every stator winding is truly exchanging at a frequency comparative to the no.of motor magnetic poles as well as the speed.

Advantages of the PMDC motor

The PMDC motors offer a host of advantages in terms of efficiency, size and cost among others.

- Smaller size: PMDC motors are a lot smaller in size which renders them suitable for use in a wide range of applications

- Low manufacturing costs: Innovations in recent years have considerably lowered the manufacturing costs of PMDC motors

- Lower cost to buyers: PMDC motors cos lower as compared to many other motors in the market.

- Ease of operation: PMDC motors do not require field winding to operate

- High efficiency: PMDC motors effectively reduce eddy currents and field circuit copper losses delivering high efficiency.

- Flexibility: PMDC motors can be constructed to encompass any size and capacity ranging from a few fractions of energy to several units of horsepower depending on the application.

Drawbacks of PMDC motors

- Demagnetization: It is impossible to compensate for the armature reaction of the PMDC motor. Hence, the magnetic strength of the motor reduces with time as the armature reaction demagnetizes. When the armature starts operating, reverses, or is overloaded, the magnetic poles are at risk of being permanently demagnetized.

- Lack of control: It is impossible to control the speed of the PMDC motor because the field in the air-gap within the motor is fixed and it cannot be controlled externally.

Applications

PMDC motors are used in a number of applications in households as well the industry. In the case of industrial use, PMDC motors can be developed to deliver up to 200 kW of power. A major use of PMDC motors is in the automobile sector where they are used to drive windshield wipers, power windows, and blowers in the car heaters or air condition units.

Other significant applications of PMDC motors include

- Toys

- Computer drives

- Portable electric tools such as drilling machines

- Refrigerators and AC units